USE OF A HEAT PIPE TO INCREASE THE EFFICIENCY OF THE HEAT PUMP

18.01.2024 14:36

[3. Технические науки]

Автор: Iryna Vashchyshak, Ph.D., Assoc. Prof, Ivano-Frankivsk National Technical University of Oil and Gas, Ukraine

Improving the efficiency of a building's energy supply system can be achieved through a variety of measures and technologies. The development of new energy efficiency technologies makes them more accessible and efficient. Installing a high-efficiency heating system, such as a heat pump, is one of the key strategies to improve the energy efficiency of a building, reduce heating costs and reduce the negative impact on the environment.

А geothermal heat pump of the flexoTHERM exclusive VWF 197 /4 type from Vaillant [1] were selected for the building's energy supply system. These heat pumps use the heat of the ground or water as a heat source.

To achieve the required heating capacity, the heat pump must have a water intake circuit of a considerable length, which takes up a large area. Due to the dense construction and the presence of underground utilities in the area where the house is located, there is no free space for such circuits. A well can be a way out of the situation. However, to ensure the required capacity of the heat pump, its depth must be quite significant. The diameter of the well must also be large due to the need to accommodate the supply and return pipelines. In addition, the downhole system must use a pump with a significant flow rate and a high power consumption.

A type of geothermal heat pump is a pump with a U-shaped well. The disadvantage of such pumps is the difficulty of forming a U-shaped well. In some cases, an analogue of a U-shaped well is an underground aquifer, which is tapped. In this case, the heat carrier is warm water from the subsoil, which is pumped by a downhole pump. However, such water requires constant filtration, which reduces the efficiency of heat generation.

The solution is to use vapour-drop heat exchangers (heat pipes) to transfer heat from the underground frost-free zone of the ground to the evaporator of the heat pump. This zone is located at a depth of 0.8-1 m. However, in order to increase the temperature, it is advisable to take the sample from a depth of about 7 m, where the soil temperature is +6 °C. In this case, there is no need for a powerful downhole pump because the heat of the earth's interior is transferred to the upper part of the heat pipe, which is wound around the evaporator coil to collect it. A low-power circulation pump is sufficient to pump the working fluid in the coil (Figure 1) [2]. This simplifies the design of the well and increases heat transfer, as a properly designed heat pipe has high efficiency.

Figure 1 – Geothermal heat pump with heat pipe

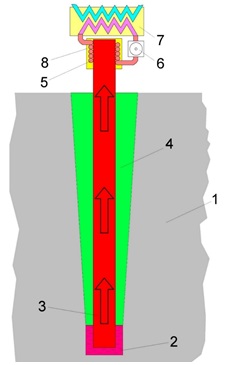

The scheme of using a heat pipe as a heat source for a geothermal heat pump is shown in Figure 2. In the ground 1, the bottom of the well 2 is filled with a certain amount of fluid with high thermal conductivity. The lower part of the heat pipe 3 is immersed in it. The heat pipe transfers heat quickly from the bottom hole to its upper end due to its high thermal efficiency. To eliminate heat loss from the surface of the tubing by heat conduction, convection and radiation, it is covered with a layer of polyurethane foam that expands from the bottom hole to the wellhead. This shape of the insulating layer is due to the gradual decrease in soil temperature as it approaches the surface. A coil 5 with a working body is wound on the upper part of the tube, which is fed to the lower section of the evaporator heat exchanger 7 by a low-power circulation pump 6. It is placed in a sealed container 8 filled with non-freezing liquid to reduce heat loss and maximise heat transfer from the surface of the heat pipe to the coil.

Figure 2 - Technology of using a heat pipe in a geothermal heat pump:

1 – ground, 2 – well, 3 – lower part of the heat pipe, 4 – thermal insulation, 5 – coil, 6 – circulation pump, 7 – evaporator heat exchanger, 8 – reservoir

Heat transfer is carried out as follows. The liquid 2 heated to the temperature of the ground at the bottom of the well gives off heat to the surface of the lower part of the heat pipe 3. The pipe is filled with a lightly boiling liquid (a mixture of alcohols), which boils at a low temperature in a vacuum. This creates a vapour stream and puts the tube into bubble boiling mode. This results in a rapid transfer of heat from the bottom of the heat pipe to the top of the pipe. The circulation pump 6 pumps the working fluid through the coil 5, which is tightly adjacent to the surface of the heat pipe. The working fluid takes the heat transferred from the wellhead and transfers it to the lower section of the evaporator heat exchanger 7. This leads to the evaporation of the working fluid in the upper section of the evaporator, which moves in a closed loop of the heat pump. The pump, in turn, ensures that the heating system operates with high efficiency.

The results of studies of heat pipes are presented in [3], which confirm the high efficiency of the use of heat pipes in heating systems. The basic expressions for calculating heat transfer by thermal conductivity, heat transfer by convection, and heat transfer by radiation are given in [4]. The formulas for calculating the optimal value of the heat flux of a heat pipe and the temperature difference along its length are also given. Based on these dependencies, the heat pipe is calculated for the selected type of heat pump.

This technology, which uses an evaporative heat pipe as a heat exchanger, significantly reduces the area required to install the heat pump's heat intake circuit, makes its efficiency independent of the season, and increases the reliability and energy efficiency of the heating system by replacing a powerful borehole pump with a low-power circulation pump.

References

1. FlexoTHERM exclusive. Technologies Vaillant. URL: https://www.vaillant.ua/dlia-klientiv/produktsia/flexotherm-exclusive-15360.html.

2. Geothermal heat pump: principle of operation. URL: https://opalennya.in.ua/heotermalnyi-teplovyi-nasos-pryntsyp-roboty/.

3. Vashchyshak I., Gaponenko V., Vashchyshak S. Study of heat pipes for heating systems in oil and gas laboratories. Oil and gas energy 2015: 4th intern. scientific and technical conf., Ivano-Frankivsk, 21-24 April 2015 р.: collection of abstracts. Ivano-Frankivsk, 2015. p. 289-293. URL: http://elar.nung.edu.ua/handle/123456789/7333.

4. Improvement of vapour-droplet heaters for the heating system of premises and buildings / Vashchyshak I., Vashchyshak S., Popovych O., E. Dotsenko. Methods and devices of quality control. 2017. № 2. р. 68-74.